The Mysterious 50 Ohm Impedance: Where It Came From and Why We Use It

When we talk about S-parameters, impedance matching, transmission lines, and other fundamental concepts in RF/high-speed PCB design, the concept of 50 Ohm impedance comes up over and over. Look through signaling standards, component datasheets, application notes, and design guidelines on the internet; this is one impedance value that comes up repeatedly. So where did the 50 Ohm impedance standard come from and why is it important? Taken in isolation, selecting 50 Ohm impedance would seem totally arbitrary: why not 10 Ohms or 100 Ohms?

The answer mostly depends on who you ask. The RF community, and particularly cable designers, have the best answer, and their analysis of coaxial cables backs up their explanation. I’ve never seen this discussed in terms of what happens on a PCB except from one expert reference, but the answer for PCBs relates back to the internal structure and electrical characteristics of common logic circuits. If you’re ready for a history lesson the 50 Ohm impedance value, then keep reading. We’ll even look into the 75 Ohm standard to see what we can learn about signal and power transfer on RF interconnects.

History of Coaxial Cables and the 50 Ohm Impedance

The history of 50 Ohm impedance goes back to the late 1920s/early 1930s, when the telecom industry was in its infancy. Engineers were designing air-filled coaxial cables for radio transmitters designed to output kW worth of power. These cables would also span long distances, reaching hundreds of miles. This means the cables need to be designed with highest power transfer, highest voltage, and lowest attenuation. Which impedance should be used to satisfy all three objectives?

As it turns out, it’s impossible to balance all three objectives, just like in many other design problems.

- Lowest loss: This depends on losses in the internal dielectric in a coaxial cable. For the air-filled coaxial, this occurs at approximately 77 Ohms, or at approximately 50 Ohms for certain dielectric-filled cables (more on this below).

- Highest voltage: This is based on the electric field between the center conductor and sidewalls in the air-filled coax cable. The electric field in the TE10 mode is maximized when the conductor is constructed such that its impedance is approximately 60 Ohms.

- Highest power transfer: Coaxial cables of any size might be long enough to act like transmission lines and support wave propagation. The power carried by a coaxial cable is limited by the breakdown field and the impedance of the cable: V2/Z. It turns out that, for the air-filled coax operating below the TE11 cutoff, power transfer is maximized at about 30 Ohms.

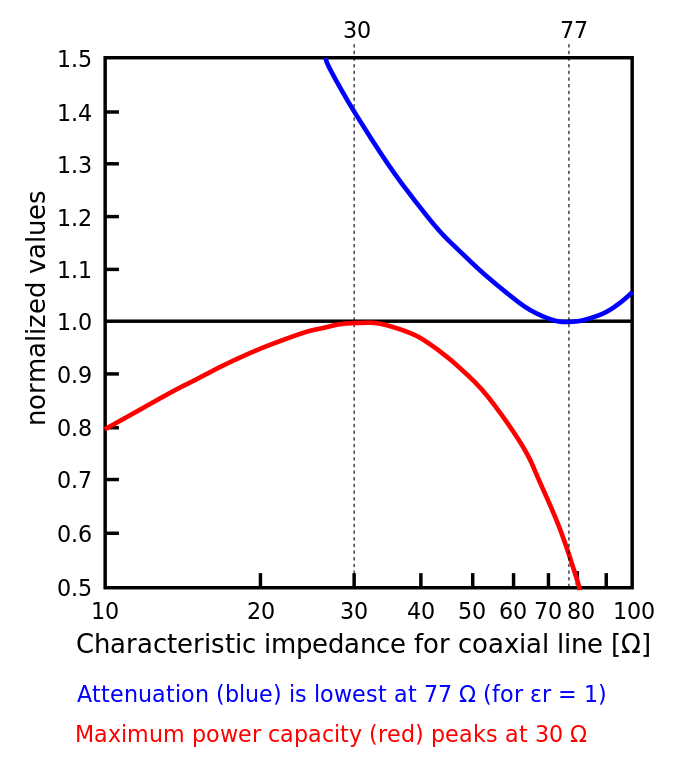

The graph below shows the tradeoff between losses and power. The file below is provided by Wikimedia, but you can find similar graphs from many other references. You can also calculate the losses using the impedance, copper roughness/skin effect, and dielectric absorption and generate a similar graph specifically for coaxial cables. The power calculation requires using the full solution for the fundamental propagating mode and the characteristic impedance.

One point to understand about the above graph is that dielectric dispersion is generally not included and will affect the results at higher frequencies. Dispersion (both Dk value and loss tangent) are taken to have flat dispersion when calculating these curves, which may not match reality within your frequency range. However, the curve gives us a good idea as to why there is the focus on 50 Ohm impedance.

Compromise or Dielectric?

The quick answer to this question is that 50 Ohms is the least bad compromise between the impedance corresponding to minimum loss, maximum power, and maximum voltage. Indeed, 50 Ohms is pretty close to the mean between 77 and 30 Ohms, and it’s close to 60 Ohms, so it seems natural to assume this is the reason for the 50 Ohm impedance standard. However, one might notice that the impedance with minimum loss in a PTFE-filled coaxial cable is just about 50 Ohms, so this seems like another natural explanation!

What About 75 Ohm Impedance?

As it turns out, the voltage value is of less importance; either you’re worried about carrying power, minimizing loss, or trying to balance the two. Low-cost coaxial cables with air or low-Dk dielectric filler can shoot for 77 Ohm impedance for long cables runs, but the reason for rounding off to 75 Ohms instead of using 77 Ohms is still a mystery to me. One would think that 75 Ohms is a nice rounded number that’s easy to remember, while an external article on Microwaves 101 claims this was an intentional design. In coaxial cables with steel core, the diameter is just slightly oversized to give some extra flexibility, so the impedance would come out to 75 Ohms. Whether or not this is true, I can’t confirm, but I’d welcome anyone contact me on LinkedIn with the answer!

Transforming Reference Impedances

When working with high-speed or high-frequency channels, we generally use S-parameter measurements as important signal integrity metrics. These are defined in terms of some reference impedance, which is normally taken as one of the above values (50 or 75 Ohms) since you might be interfacing with one of these media in your high-speed/RF system. I prefer to think of reference impedance in terms of your desired termination impedance; you’re shooting for 75 or 50 Ohm impedance at each port, and S-parameter measurements show you how you’ve deviated from this goal in your design.

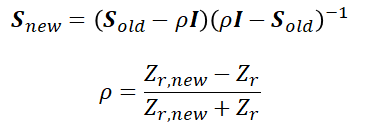

If you have a measured S-parameter matrix for an interconnect on your PCB, you can transform it to a new S-parameter matrix with the following transformation:

This is useful for understanding how your S-parameters might change when you switch your reference media (e.g., between 75 and 50 Ohm impedance cable). By using the term “reference media”, we’re making a comparison between our DUT/interconnect and an idealized 50/75 Ohm cable, 50/75 Ohm port, or another component with 50/75 Ohm input impedance.

Whether you need to design to 50 Ohm impedance or some other value, the PCB layout features in Altium Designer® include the tools you need for high-speed design and RF design. You can access the integrated 3D field solver from Simberian in the Layer Stack Manager to implement impedance control in your PCB stackup.

When you’ve finished your design, and you want to share your project, the Altium 365™ platform makes it easy to collaborate with other designers. We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.