What They do not Teach you About Capacitors

In engineering, we often adopt hundreds of mental shortcuts in order to keep the complexity of the topics we tackle to a manageable level.

If we were to run a quantum-physics simulation every time we flash an LED, we would never get anything done. Yet, many of these shortcuts and rules-of-thumb were created in times past , when the electronics industry was radically different than what it is now.

Today, we are going to unlearn what a capacitor is. In addition, we’ll discuss how to use capacitors, by taking into consideration contemporary electronics.

What A Capacitor Is Not (Anymore)

One of the common assumptions is that the primary role of a capacitor is to store charge, like a water bucket being filled by one cup and emptied with another at the same time .

If you’ve ever gotten into a discussion about “whether current flows through a capacitor” and veered more into politics than physics, you know that typical analogies don’t make much sense when AC current is involved. A capacitor is merely two conductors separated by a dielectric, and nowhere in basic physics explanations of its properties will you find an explanation of what you should do with it.

Storing energy is just one of a capacitor’s many uses, as is filtering, shaping, or altering electrical signals and impedances. We tend to think of these as its primary use because it was its first use at the dawn of DC electricity and William Gilbert’s electroscope — invented in the 15th century.

A Capacitor’s Role

Terms like decoupling and bypass capacitor are often used interchangeably — I’ve made this mistake countless times myself.

This leads to much confusion, as different uses often require capacitors with different electrical and physical parameters, such as packaging, voltage ratings, ESR (Equivalent Series Resistance), ESL (Equivalent Series Inductance), and self-resonance profile.

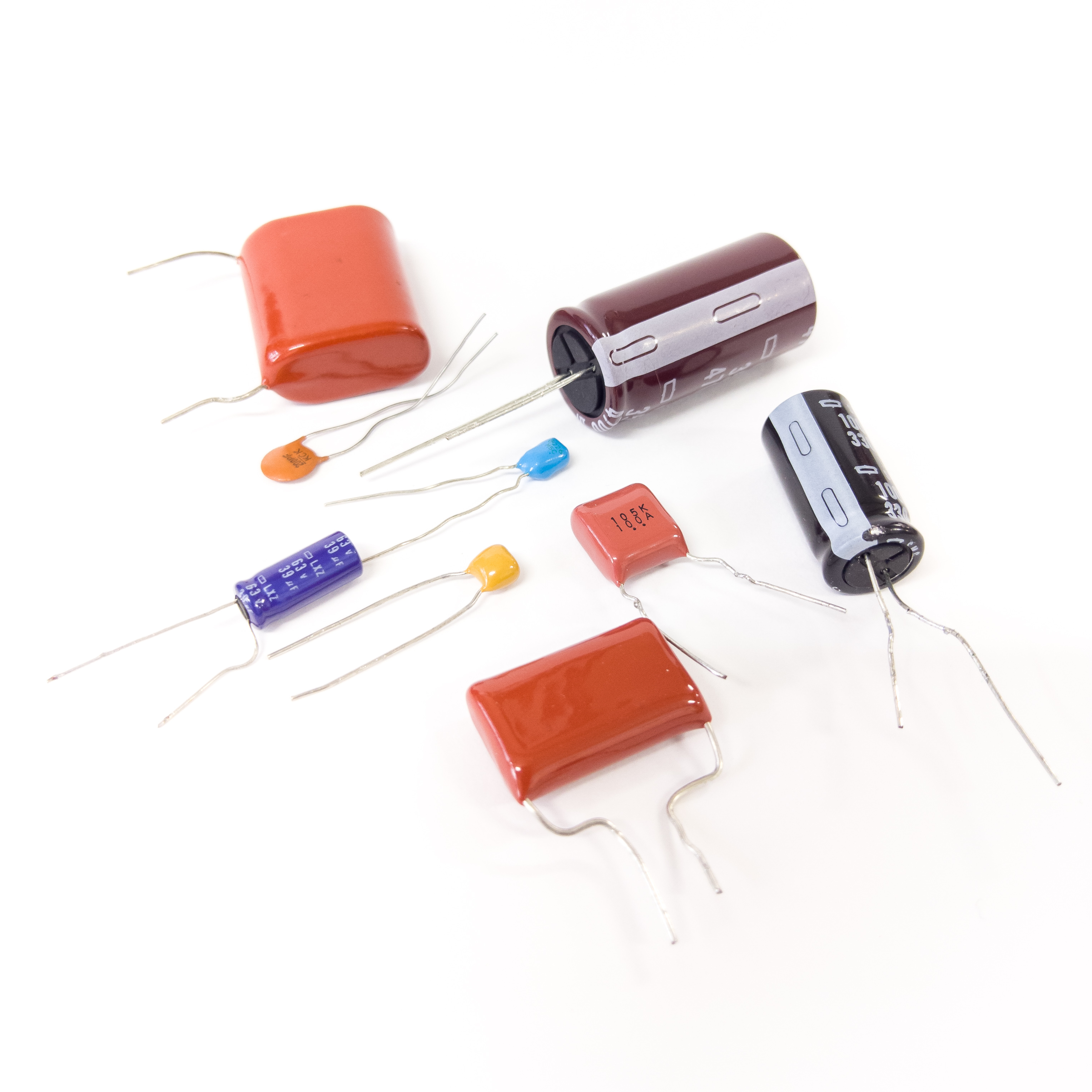

Capacitors take different names based not only on the technologies they’re built on (ceramic, electrolytic), but on their roles as well.

The following sections contain some of the most common roles taken on by capacitors.

Bypass Capacitor

The role of a bypass capacitor is to transfer RF (reasonably high-frequency AC) energy from one part of your board to another. As you’ve just read, there is no talk about storage whatsoever. None! A bypass capacitor is all about conducting, not storing.

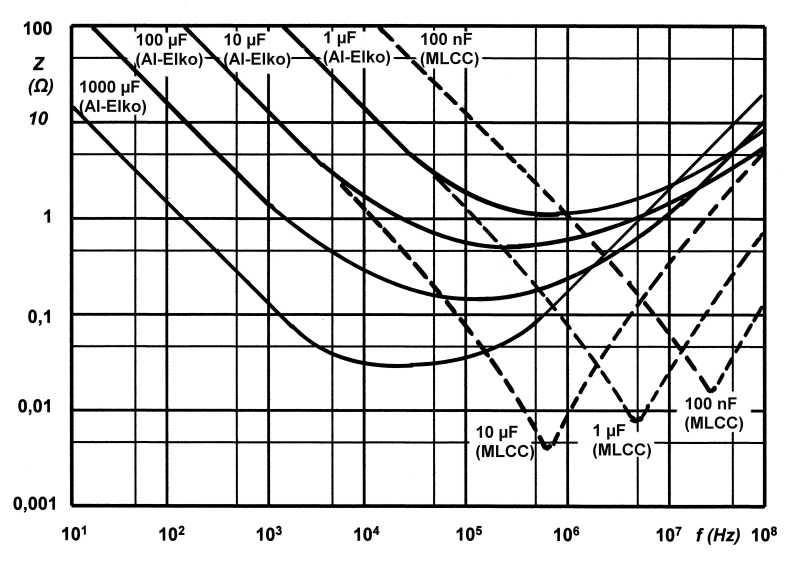

For this to happen, the capacitor has to be carefully selected with the lowest impedance possible at the frequencies of interest. This can be achieved by matching its self-resonant frequency to the RF signal as much as possible.

The self-resonant frequency is the frequency at which the capacitance and the parasitic inductance of the capacitor resonates, and the capacitor presents the lowest possible impedance. Mathematically, it’s like capacitance and inductance disappear, leaving only the equivalent series resistance.

For frequencies higher than the self-resonant frequency, the capacitor starts to behave less and less like a capacitor and more like an inductor.

What to Watch Out For

One of the most common mistakes made when using bypass capacitors to keep electromagnetic emissions in check (especially when trying to bypass on the ground planes), is limiting their placement only at the source of the noise we want to address.

In DC this would make sense: short the signal as close to the source as possible to get its values as low as possible, minimizing resistance (impedance) between the electrical short ( the capacitor) and the source.

In AC, and especially in the RF domain, due to the wave-nature of electrical signals, the rapid increase in impedance between the area near your noise source and the rest of the ground plane can be a source of reflections. This can happen on traces as well, as the higher impedances of vias can reflect the RF energy.

That’s what reflections are: energy reflected due to mismatched impedance. Again, this conflicts with the traditional description of “energy reflected due to unterminated lines”, which is only partially correct.

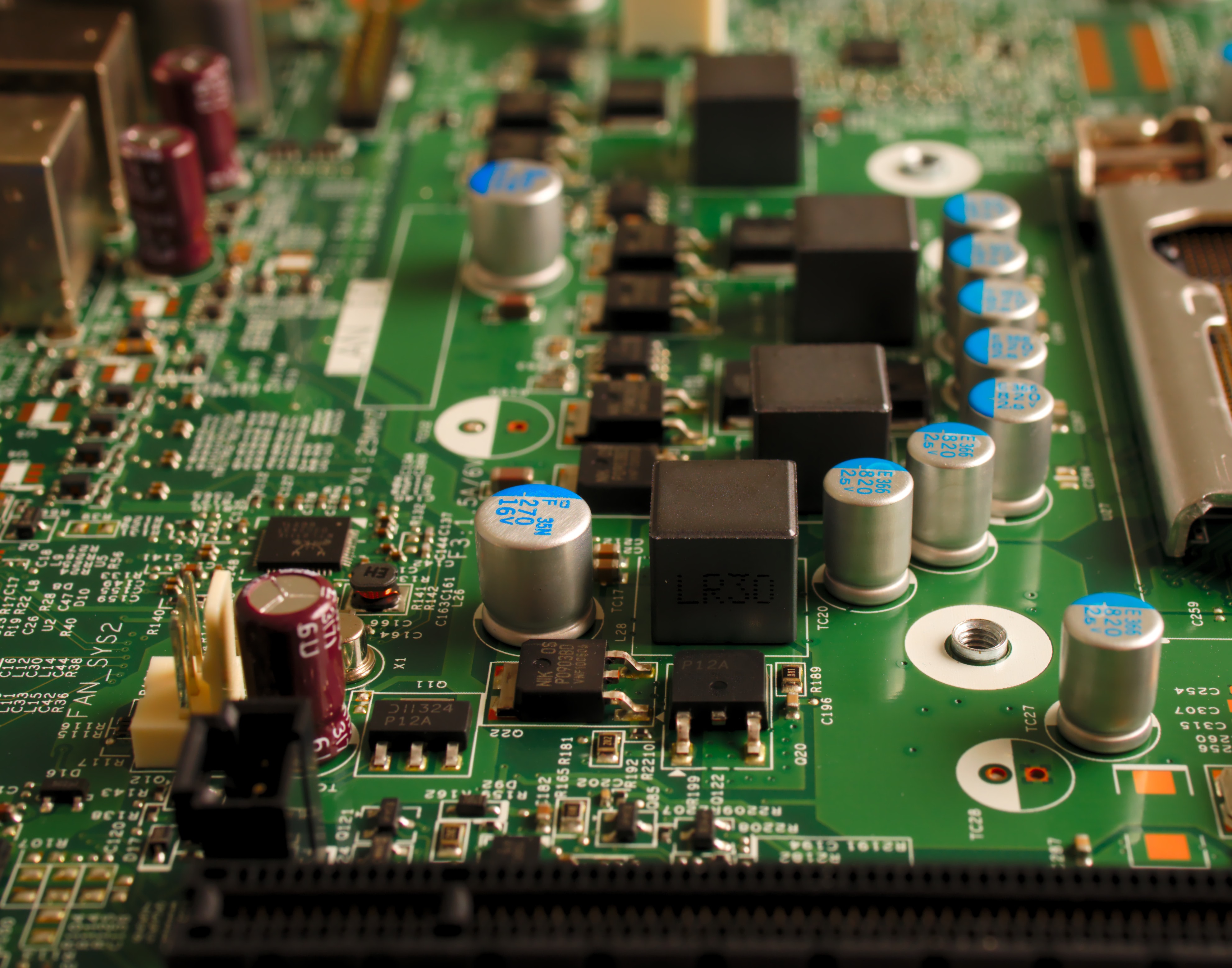

When using bypass capacitors, you should try to lower the impedance of power and ground planes by spreading capacitors across your boards. Depending on the frequency you want to address, the layer stack-up, and the dielectric material of the PCB, you might want to consider capacitors in the picofarad to nanofarad range.

Decoupling Capacitor

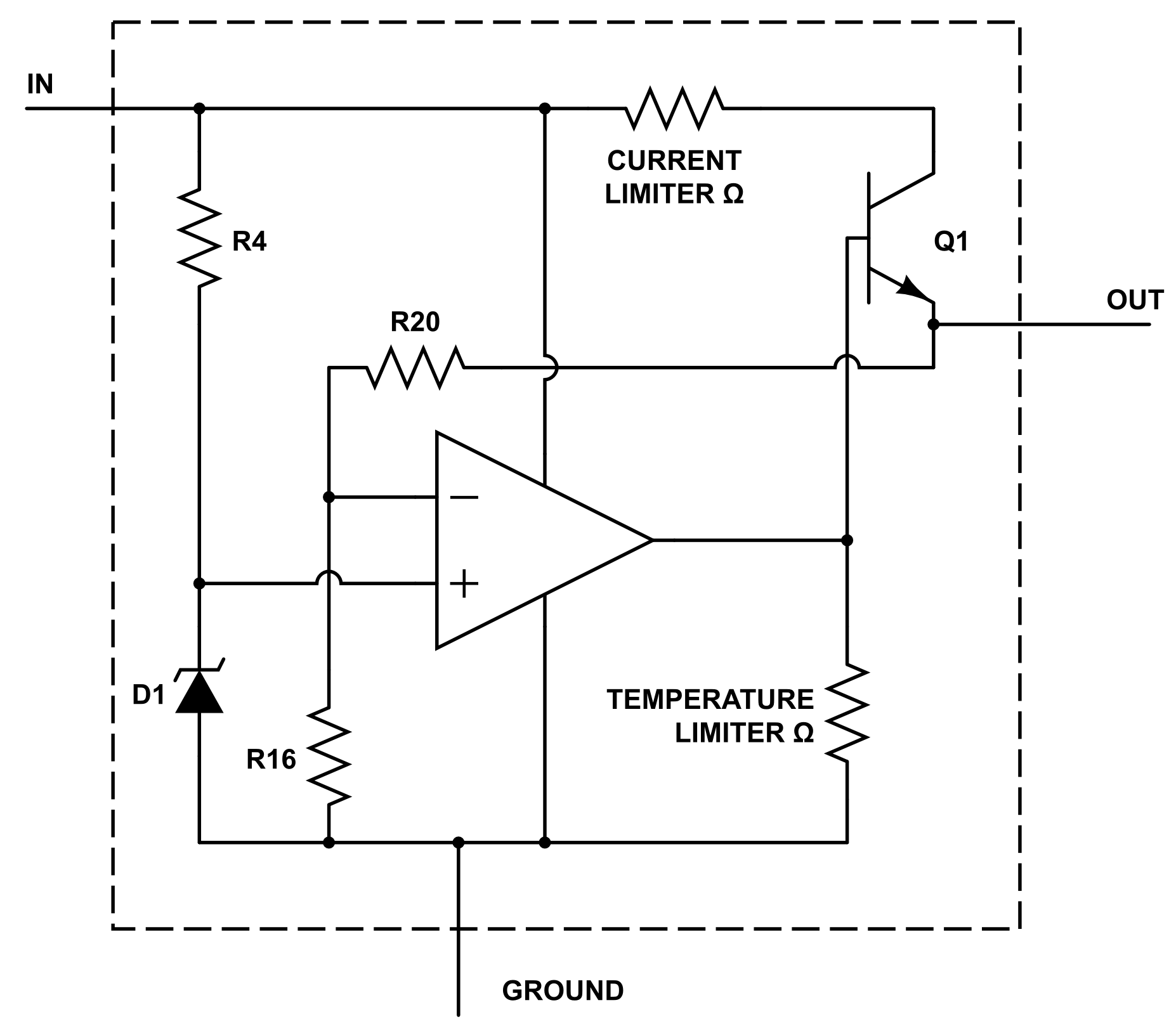

Linear regulators like the ubiquitous 7805 have an internal feedback loop that compares the output voltage with a voltage reference and regulates the current accordingly to maintain a stable output.

In theory, linear regulators could be used without an external capacitor — at least if we ignore any issues of self-induced oscillation. To obtain a stable output, the current being demanded would need to change at a slow enough slew rate for the linear regulator to follow. Given most of them are built on early 80s BJT technology, those slew rates are not fast at all.

Similarly, switching DC-DC converters have a fundamental switching frequency and cannot regulate the output faster than this frequency.

Many modern digital devices generate current transients with frequency components of hundreds of megahertz, way more than any regulator can follow (unless we’re talking about exotic laser-diode drivers).

Decoupling capacitors operate on the borderline between the stable voltages regulated by the DC power supply circuitry and the intermittent current consumption of modern digital devices.

Even a small impedance between the power supply and the device, when faced with a current peak, will quickly lead to a supply voltage outside the acceptable ranges.

The decoupling capacitors act as temporary localized energy storage, effectively reducing the source impedance for values between a few megahertz and a few hundred megahertz.

For frequencies above the hundreds of MHz, most SMD capacitors present a high impedance and are ineffective, techniques like buried capacitance in the layer stack need to be used instead.

What to Watch Out For

Decoupling capacitors are only useful in a relatively narrow frequency band, mainly due to the limitations introduced by their parasitic properties.

The main parameter to watch out for is, once again, the self-resonance frequency. Decoupling capacitors are effective only at frequencies lower than their self-resonant frequency.

The following rules of thumbs are often useful to choose what capacitor to use:

- DC to ~Khz: no capacitor is needed, the power supply can keep up by itself.

- ~Khz to ~Mhz: the high values of electrolytic capacitors are beneficial for the lower frequency range, but their high series impedance limits their performance by inducing a low self-resonant frequency. At the Mhz range, many electrolytic capacitors are already heavily inductive.

- ~Mhz to 200Mhz: ceramic capacitor, depending on the dielectric, package size, and building technology, usually cover this range.

- Above 200Mhz: ceramic capacitors start to become ineffective. In this scenario, it would be best if you used buried-capacitance techniques instead.

Bulk Capacitor

Bulk capacitors are used to keep the voltage stable during missing power line cycles and support peak current demand, and are usually electrolytic due to the high capacity needed for this role.

Think of them as tiny, adorable, cylindrical UPS (Uninterruptible Power Supply).

What They Don’t Teach You About Ceramic Capacitors

Ceramic capacitors are undoubtedly the quintessential passive component in today’s electronics industry, and their volumetric capacitance has been improving at a comparable rate to transistor density in silicon, enabling much of the modern high-density design.

They are indeed a marvel of technology, but they also have a few quirks you should be aware of.

Smaller is Better

Ceramic is a wonderful material, but it’s also brittle. Ceramic capacitors can crack due to flexing of the PCB board, for example during assembly of larger boars (or panels), snapping v-cut boards apart improperly, or if the products are mishandled during shipping.

Flex-cracking is a dangerous phenomenon: if the capacitor is used on power lines capable of high currents, it can often fail-short and cause a fire.

Contrary to popular wisdom, a smaller capacitor has both superior electrical and mechanical performance. They’re less likely to crack and have a higher self-resonance frequency.

If your product needs high reliability under mechanical stresses, there are a few techniques that you can use to reduce this kind of failure.

- Don’t place capacitors with the long side in the same direction as the board flexes.

- Use smaller capacitor like 0402

- Use soft-terminated capacitors that don’t short under stress, and/or X2/Y2 rated ceramic capacitors that short open

- Route around your capacitors to relieve mechanical stress

- Assuming you have chosen capacitors that break-open, always use at least two of them in parallel, so that your circuit may have enough capacitance to continue operating normally when one of them breaks

Dielectric Counts, a Lot

C0G, X7R… dielectrics have weird names and a mixed-bag of properties. Here are their characteristics and when they shine.

- C0G/NP0: These are the fanciest ceramic capacitors on the market. Typically, they are available from 1pF to 100nF and have a 5% tolerance. NPO stands for positive-negative-zero, the shape of the capacitor’s coefficient graph, which looks flat over the temperature range. They’re what you should use when precise values and stability are required.

- X7R: The modern workhorse. They have excellent voltage and temperature coefficients and are popular between 100pF and 22uF. They’re the most widely used for decoupling applications and have a wide temperature range of -55°C to 125°C.

- X5R: Similar to X7R but rated for 85°C instead of 125°C.

- Y5V: Can reach extremely high capacitance value but with low voltage and temperature ratings (up to a loss of 82% of capacitance allowed).

- Z5U: Similarly to Y5V, Z5U capacitors display poor voltage and temperature performance and are extremely cheap. Rated only down to -10°C. Used only in low-cost consumer equipment for decoupling.

What to Watch Out For

Matching capacitors with different dielectrics can lead to unexpected results.

For example, Z5U capacitors are very affordable and use a barium titanate dielectric. This material has a high dielectric constant, enabling an excellent capacitance-to-volume ratio, and a self-resonant frequency commonly between 1MHZ and 20 MHZ.

NPO performs better at frequencies above 10Mhz, so why not mix and match them to get a wide-frequency performance?

Unfortunately, when Z5U and NP0 capacitors are connected in parallel, the higher dielectric constant material dampens the resonant frequency of the NPO, and the combination results in a worse overall performance than just a good-quality Z5U.

The “why’, however, is definitely beyond my paygrade. If you understand this phenomenon, please write me a letter.

Dielectric Absorption

If you short the output of a charged capacitor, you will find yourself with a completely discharged capacitor sitting on your bench and staring at you with saddened eyes. This, however, is not always the case. Almost all capacitors, with the only notable exception of vacuum capacitors, retain part of their charge after being discharged.

The phenomenon happens because the randomly-oriented molecular dipoles are aligned over time by the electric field, and their newly-found orientation is retained even in its absence.

Ceramic capacitors can retain up to 0.6% of the charged voltage for NP0 and 2.5% for X7R.

Voltage-Dependent Capacitance

Y5V capacitors can lose up to 82% of their capacitance at the rated voltage, while NP0 capacitors have an almost-flat response.

If you have applications where you must vary the output voltage, for example through the configurable voltage source required by the USB-PD standard Mark Harris discussed in his recent article, you might find yourself with apparently unpredictable circuit performance.

The design tools in Altium Designer® contain everything you need to keep up with new technology. Talk to us today and find out how we can enhance your next PCB Design.