What is ISO 14300

In looking for the answer of what is ISO 14300, find out about space exploration device requirements and the potential behind CAD tools.

ALTIUM DESIGNER

PCB Design software with excellent communication through the design process.

The International Standards Organization (ISO) represents 163 national standards bodies and functions as an independent, non-governmental entity. ISO meetings bring experts together to share knowledge and to gain consensus about the development of world standards that respond to global-scale innovation and challenges. Because companies adhere to globally developed ISO standards, international trade occurs smoothly.

The 22,513 standards published by the ISO cover design, manufacturing, and distribution processes and systems for almost all industries. As a result, product specifications become standardized across global markets. Companies and corporations that align their processes and produces with ISO specifications ensure quality, safety, and efficiency.

ISO 14300-2:2011 defines product assurance policies, objectives, principles, and requirements related to space exploration programs. The standard covers the definition of the mission, anything related to the mission design, and the development, production, and operations of space products. As defined by 14300-2, product assurance covers product assurance management, quality assurance, safety assurance, the assurance of software and hardware systems, materials, and process assurance.

Altium Designer Aligns with the ISO 14300 Standard

In terms of PCB design, the ISO 14300 product assurance policy covers electrical, electromechanics, electronic components as well as mechanical parts used for space exploration. An in-depth review of the ISO 14300 standard shows that the policy also includes contractor relationships and outsourcing, design for manufacturability testing, design rule, and electrical rule checks, and geometric constraints. Given the specifications found within ISO 14300, the standard affects every part of the PCB design process through fabrication and manufacturing.

Design teams have the responsibility for verifying that the PCB design and testing processes respond to precise quality standards. Creating a design that complies with the ISO 14300 begins with the components and the first decisions that a design team makes about the project. Each decision about components and the schematic factor into the design rules, layout, testing, documentation, and packaging.

Altium Designer Lists Verified Parts Suppliers

One significant part of the ISO 14300 standard focuses on the procurement of high-quality and special-purpose components. In addition, the standard addresses the working relationship between PCB design teams, contractors, and outsourcing. Altium Designer allows your team to comply with the ISO 14300-2 standard by linking design components and supported suppliers and by providing live supplier-produced parts information. Altium Designer lists some suppliers as Verified to show that the particular supplier has partnered with Altium in the aggregator service as an Altium Parts Provider. Each Altium Parts Provider has proven component stock and trustworthy data feeds.

With access to real-time supplier parts information, design teams can verify the availability of ISO 14300-2 compliant components. Altium Designer allows members of a design team to search across a supplier’s product catalog, integrate the component data sheets, parameters, and pricing information into the design, and place the component on a schematic sheet.

- Learn more about creating and linking to parts supplier data easily

- Learn more about integrated component libraries and how they help make accurate supplier databases

- Learn more about new supplier parts updating

Establish DFM and Ensure ISO 14300-2 Compliance with Altium Designer

Compliance with the ISO 14300-2 standard involves defining the operational parameters of the PCB design and using the verified components, materials, and processes. Altium Designer helps design teams address compliance specifications through the Bill of Materials Analysis and Management features. Within the unified environment of Altium Designer, ActiveBOM allows multi-functional teams to work together to achieve Design for Manufacturability performance.

Altium Designer’s ActiveBOM provides advanced features that assist design teams with finding parts that match arrangement and interconnection needs. ActiveBOM responds to DFM requirements by applying best practices for selecting parts that not only simplify fabrication but also provide commonality with other designs. For example, the combination of ActiveBOM with Altium Cloud Services provides live parts information from a list of approved external suppliers and continuously pushes information about costs, stock levels, and minimum order quantities into the ActiveBOM.

Design teams can add custom Bill-of-Material items or parameters that support the PCB design project to ActiveBOM. As a result, PCB design teams can manage electronic components and mechanical parts beyond the components initially specified within Altium Designer’s Schematic Editor. Design teams can generate the Bill-of-Materials directly from the ActiveBOM editor.

Achieve the Quality Needed for ISO 14300-2 Compliance with Altium Designer

Every defect—and the processes used to discover and solve detects--add cost to each stage of a design project. Altium Designer allows design teams to confirm the quality of components arriving from reliable sources and comply with design specifications. With every update, ActiveBOM automatically checks each Bill-of-Material item for violations. Each check verifies that items match library parameters and that the item includes accurate cost and supplier information.

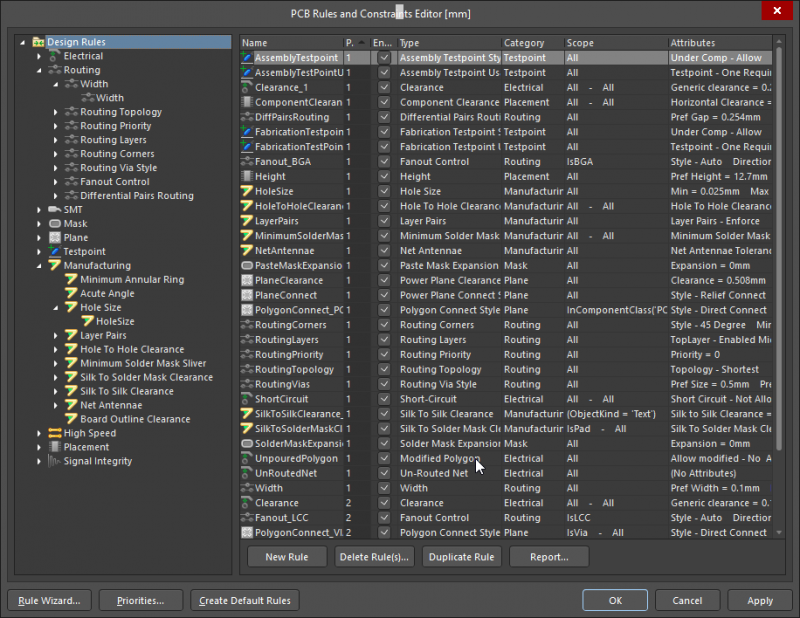

Achieving design for manufacturability involves having the appropriate number of constraints. Too many constraints increase electrical and mechanical tolerance demands. Having less than the minimum number of constraints affects quality. Altium’s design rule checks, electrical rule checks, and simulations ensure design and product quality by correctly defining constraints. Altium Designer’s Design Rule Checker fortifies the quality approach by establishing specific design guidelines and optimal tolerances for the PCB components, schematic, and layout.

- Learn more about constraint-driven versus rules-driven design.

- Learn more about layout considerations for length tolerance matching

- Learn more about PCB hole size tolerance matching

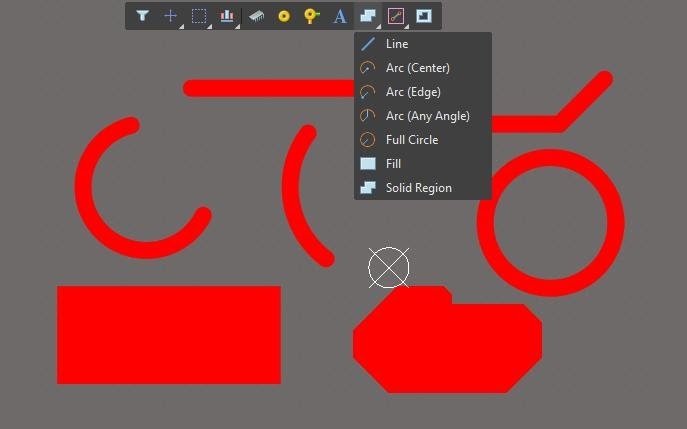

Creating shapes in your layout with easy integration into rules and design processes helps

Build Design for Manufacturability with Altium Designer’s ECAD/MCAD Collaboration

Design teams working within Altium Designer utilize complex hierarchical schematic capture and design tools and PCB layout tools. Schematic capture allows teams to build designs in sections and to capture the sections on separate schematic sheets. Altium Designer also addresses the complexity of rigid-flex and multilayer designs with the layer stack manager.

Working with 2D tools, design teams can use the Enhanced Layer Stack Manager to achieve the correct single-sided and differential impedances. The Stack Manager addresses layer pairing, rigid-flex requirements, and layer stack symmetry. Given these capabilities, design teams can define multiple PCB layer stacks and assign different layer stacks to different rigid-flex design zones.

With a complete range of 2D and 3D tools, Altium Designer controls and manages the ECAD/MCAD design process. Altium Designer allows your design team to seamlessly switch between 2D and 3D editing modes. With this capability, electrical and mechanical design teams can simultaneously use unified MCAD tools to verify the physical aspects of the design make any adjustments to the schematic and PCB layout.

3D visualization allows the PCB design to include mechanical details as well as electronic details. Switching to the 3D display and viewing the stack-up allows another evaluation of the component placement, routing, and check for any possible collisions between components or between components and enclosures. As a result, designs quickly progress from layout into the prototyping, manufacturing, assembly, and manufacturing stages of the project.

Mixed Signal Circuit Simulations Builds Compliance with ISO 14300-2 Specifications

Altium Designer ensures quality with signal integrity analysis, mixed-signal circuit simulations, and power integrity analysis. Each of these tests establishes the quality assurance required for ISO 14300-2 compliance. The signal integrity simulator models the behavior and interaction of circuit transmission lines through the use of algorithms.

Altium’s post-layout signal integrity analysis offers a detailed look at the behavior of circuit routing and checks for mismatched net impedances. Altium’s PDN analyzer ensures the effectiveness of the DC power delivery systems for a PCB design. The DC analysis tests the planes, traces, and vias that provide the power consumption requirements for the PCB. Because the signal integrity screening functions as part of the Altium Designer’s design rules system, design teams can use the Design Rule Checking system to check for signal integrity violations.

- Learn more about Altium Designer's smart component placement.

- Learn more about making the most of rules-driven design software.

- Learn more about utilizing Design for Manufacturing (DFM) principles to maximize production yields.

Managing the influx of design vulnerabilities with a smart rules-checking engine

Creating an ISO-14300-2 compliant requires attention to the details. The unified design environment seen with Altium Designer builds the compliance foundation with tools that verify the quality of components, design rule checks, 2D and 3D layout and visualization tools, testing, and documentation.