Power Electronics for Lithium Iron Phosphate Batteries in Altium Designer

Power electronics encompasses a massive list of systems that make modern life possible. From automotive systems to power distribution systems, power electronics are responsible for controlling and managing the flow of power throughout an electrical system. With alternative energy systems bound to become more popular in the future, engineers and designers need the right PCB design software for power electronics systems.

Design software for power electronics systems must include access to massive component libraries and management features, as well as tools that show the link between power distribution and hot spots in PCBs. With Altium Designer, you can take control over every aspect of power electronics for lithium phosphate batteries. You’ll have access to all these features and more in a single interface.

ALTIUM DESIGNER®

A unified PCB design package with design tools for power electronics and distribution applications.

Fossil fuels are going out of style and will slowly be replaced with alternative energy sources like solar farms and wind farms. Energy management is an important topic in the research literature, and scholars have seriously explored the use of a number of methods for storing energy during lapses in power generation. These methods include the use of lithium phosphate (more specifically, LiFePO4) battery arrays, which allow energy to be released back into the grid when generation drops.

Lithium-ion batteries are not relegated to power storage systems. These batteries are found in mobile devices, batteries for electric and hybrid vehicles, and other electronics that require rechargeable batteries. Charging systems for these batteries must meet similar demands as charging systems for energy storage, albeit at a smaller scale.

What to Know About Lithium Phosphates in PCB Design

Power electronic systems for lithium phosphate batteries must be designed to regulate the charging rate and prevent overcharging. An overcharged battery can produce excessive hydrogen and oxygen gases as the electrolyte heats up to a high temperature. With fully sealed batteries, this buildup of gasses can create a danger that the battery will burst. This reduces the overall lifetime of the battery. Without a power management and protection system, the battery can also overheat, creating a risk of fire in extreme cases. Lithium phosphate batteries have lower output energy density than other lithium-ion batteries, thus they tend to be safer.

Power Management System Requirements

Power management systems for rechargeable lithium-ion and lithium phosphate batteries need to regulate the charging voltage/current and limit the charging current to prevent overcharging. These systems should also ensure that the discharge rate can be controlled or suppressed in the event of a short, helping extend the lifetime of batteries.

These power electronic systems for controlling charging and discharging of batteries must be built to meet other important operating demands. These systems will be thermally cycled throughout their lifetime more often than most PCBs. These systems will also carry high current, thus they must be designed to withstand higher temperatures than other PCBs. The electrochemical environment in which these electronic systems operate puts them at risk of corrosion.

- If you are planning to use a battery to run your next mobile device or provide emergency power, you have plenty of options to choose from.

Learn more about lithium phosphate and ion batteries in PCB design.

- Power distribution systems and battery arrays often run at high voltage and current, and they require specialized design techniques to ensure reliability.Learn more about PCB design for high voltage power systems.

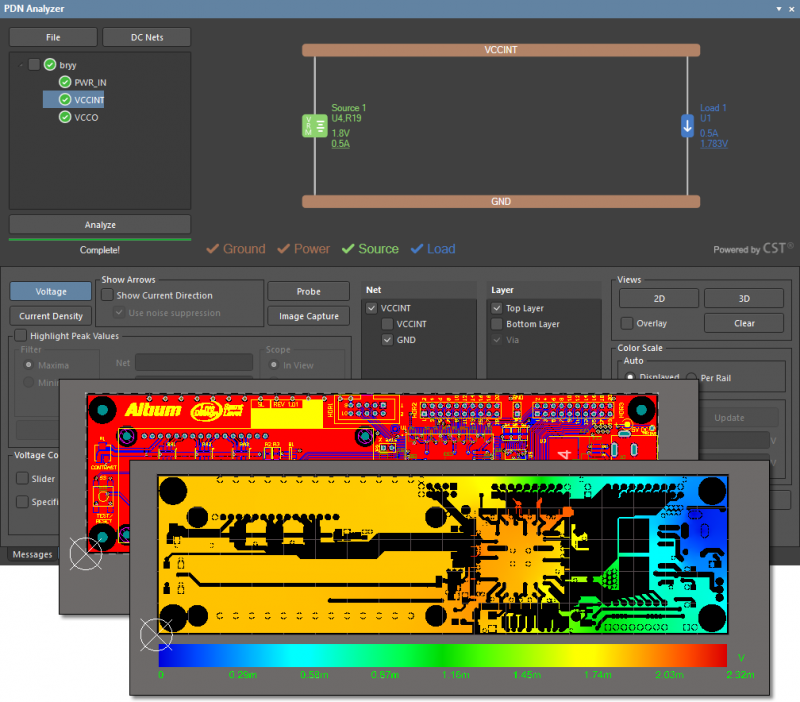

- Designing power systems is much easier when you use a power delivery analysis tool when designing power electronics.Learn more about incorporating PDN simulations in power electronics design.

Preparing a power delivery network simulation in Altium Designer

Battery Power for Embedded Systems

Embedded systems make their mark in several areas, ranging from aerospace to automotive and military systems. With more processing power being packed into PCBs for these systems, and with increasing mobility and uptime requirements, designers need to consider the power consumed in these systems and choose the appropriate power management strategy geared specifically towards battery power. Engineers have a major role to play in developing power management methodologies for electronics in embedded systems.

Thermal and Battery Power Management in Embedded Systems

Designers and systems engineers need a number of important tools that go beyond PCB layout features. As embedded systems include processing capabilities, power consumption can be periodically reduced when designers configure their processors to enter sleep mode when not in use. This will make a huge impact on the power consumed in your embedded system and will increase the lifetime of components on the board. The power management portion of the system must then react to ensure that the charging and consumed power are limited to acceptable values.

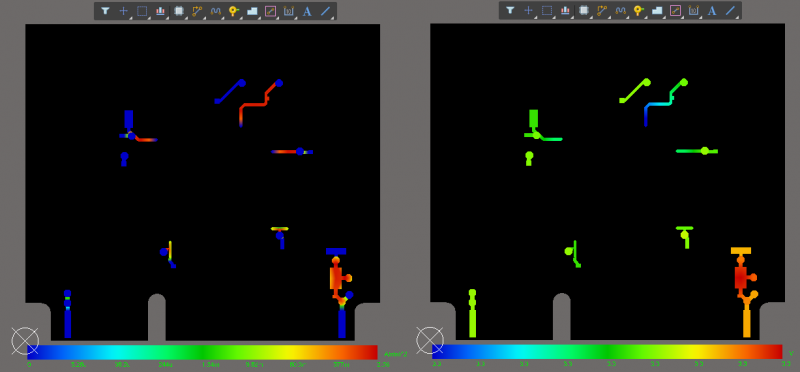

Aside from using lower power components, identifying and eliminating hot spots in PCBs helps extend the overall lifetime of the system. Ensuring power delivery with minimal losses and proper thermal management is possible when designers use a power delivery network analyzer that is built into their PCB design software. This type of simulation allows designers to easily identify hot spots in their device during operation and experiment with potential redesigns.

- Power distribution network design might seem difficult, but it doesn’t have to be when you work with the right simulation package.

- Once your batteries begin supplying power, you need to make sure your power delivery network can deliver energy to your system with minimal losses.

Learn more about power delivery system design with Lee Ritchey.

- You might need a regulator for your power management system, and you’ll need to decide which type of regulator will satisfy your power requirements.Learn more about selecting a voltage regulator in your power management system.

Identifying hot spots in a power delivery network

Power Management Systems Design in Altium Designer

Given the complex requirements on power management systems in lithium phosphate battery powered PCBs, your design software must include capabilities that integrate your design, component management, and analysis features into a single environment. Designing power management capabilities for embedded systems requires organizing your power management, regulation, and data processing functionality into hierarchical schematics. This process is much easier when you work with hierarchical schematic design tools in your PCB design software.

Altium Designer: The Only Unified PCB Design Platform

The right design software can help you design and verify the functionality of your battery power management system without having to switch between design programs. Only Altium Designer places your essential design features within a single program. The hierarchical design features help you stay organized, and the simulation features help you verify the functionality of your battery charging and management system.

- Designing any power management system requires working with a schematic editor. Altium Designer takes a multi-channel, hierarchical design approach to schematic creation, allowing to include complex functionality in your board while staying organized.Learn more about hierarchical multi-channel schematic creation in Altium Designer.

- Pads and vias are important elements for thermal management and must be designed properly.See how Altium Designer is changing PCB via and pad design.

- Power delivery analysis is critical for identifying hot spots, ensuring maximum power is delivered to components, and estimating power consumption throughout your power management system.Learn more about working with Altium Designer’s PDN Analyzer extension.

Working with the right design software will help ensure that your battery charging and power management system contains all the capabilities required to run properly. With Altium Designer, the design tools you need for building power management systems are present in a single program. You can access design, power distribution network analysis, and verification tools in a single interface.

When you work with Altium Designer, you’ll have access to the tools and resources you need to be successful. You’ll have instant access to the AltiumLive forum, webinars, and podcasts with industry experts, and an extensive knowledge base filled with design tips and tutorials. No other PCB design software company gives you this many resources for success.

While other PCB design software platforms are busy separating their tools into different programs with inconsistent workflow, Altium Designer unifies essential design features in a single environment. Don’t settle for other design platforms that sap your productivity. Instead, you need to work with the best software: you need Altium Designer.