Making Value Chain Management Work for Electronics

There’s an essential concept for project managers and product owners that needs to be considered during the design phase: value chain management. This sounds like some vague term from a business textbook, and it isn’t often considered until you get to the corporate level. However, defining your design requirements with the value chain in mind is important for ensuring profitability while also delivering the most value to the end user. Here’s how you can manage new designs and a larger product portfolio with the value chain in mind.

What is Value Chain Management?

Value chain management is one of those concepts that are central to any business venture where tangible goods are produced. Still, you probably won’t ever hear it mentioned in business classes. It’s often discussed in the context of supply chain and logistics, but value chain management is not the same thing as supply chain management. Instead, value chain management aims to maximize the value (whether real or perceived) added to a product’s raw inputs throughout the value chain. The value chain encompasses the entire procurement, design, production, marketing, and distribution process.

If this sounds a bit like supply chain management, that’s understandable as the two concepts are related. Maintaining a competitive and responsive supply chain is key to successful value chain management. Still, the product itself has a role in maximizing the value delivered to the end customer or user. Besides, the manufacturer has a role to ensure the end user sees maximum value when they use the product.

Informing your Design Process

The basic business functions that go into value chain management are marketing, sales, and distribution/logistics. When we dig deeper, there are three areas where electronics designers can maximize value to the end user. If you can develop the right product development process, you can maximize value for the end user as you transition from ideation to design and manufacturing. I’ve summarized these three areas in the table below.

|

Ideation |

Clearly define: |

|

Design |

Schematic design |

|

Procurement |

During ideation: |

|

Production |

● Compile documentation, deliverables, and test requirements |

The great thing about value chain management in the above areas is that it fits within other design methodologies for electronics and hardware (e.g., agile development). The connection back to the value created for the end user is not always clear just from looking at the above list. Note that “value” can mean more than just a lower price for the consumer or lower the designers’ expenses. Let’s look a bit deeper in each of these areas to see how value gets created:

Ideation

Clearly define your requirements early, and your designers will have no questions as to what they are designing. You also reduce the chances that an important feature set was missed during development. In both cases, you reduce the risk of a redesign later. You might get prototypes back from your fabricator that don’t meet the functional or customer requirements in the worst case. Anytime you prevent a failed prototyping run, you get to market that much quicker and reduce development costs.

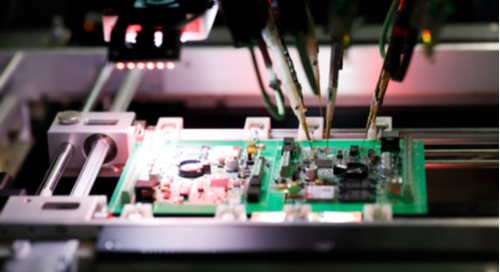

Design

This is where the rubber meets the road for PCB designers. Successful PCB design is about more than your schematics and layouts. It’s about getting the product off your computer screen, onto the manufacturing floor, and into your customer’s hands. With clear requirements in hand, your team can get through the design phase faster.

.jpg)

Procurement

Getting the best deal on price for your desired components cuts overall production costs or the price paid by the customer (or both). The other side of the coin is the lead time, and ensuring orders can be filled when needed. No one will want to order your product if you’re continually battling component shortages and waiting for raw materials to hit the factory floor. Proper supply chain monitoring and management with the right supply chain tools will help you stay ahead of shortages and price changes.

Production

Your manufacturer needs a clear set of documentation and design data to ensure your board is produced, tested, and assembled correctly. Speaking with your fabricator/assembler early to get their requirements can help you reduce lead time and cost and prevent a pre-production redesign.

Success in these four value chain management areas translates into higher quality products, lower costs and prices, and shorter lead times. Successful cross-functional teams and their product managers need to excel in these areas to stay competitive. If you’re managing a cross-functional team, your team needs the design and collaboration features found in Altium 365. This cloud-based platform integrates with Altium Designer and apps like Altium Concord Pro and the Altium Viewer. You’ll have access to a complete collaboration and supply chain solution for your value chain management process.

Altium Concord Pro on Altium 365 is bringing an unprecedented amount of integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what is possible to do with Altium Concord Pro on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.