Design for Manufacturing and Assembly (DFM/A) or Predictive Engineering

Advances in interconnection technologies have occurred in response to the evolution of component packages, electronic technology and increasing complex functions. The printed circuit, therefore, has become the most popular and cost-efficient way to physically execute an electronic circuit.

Fabrication, assembly and test technologies have responded by making their technologies more complex. The increased complexity and capabilities have made selection of technologies, design rules and components so complex that a new function has developed to allow for the prediction and selection of design parameters and performance versus manufacturing costs. This is the planning for design, fabrication and assembly. This activity has also been called design for manufacturing and assembly (DFM/A) or sometimes predictive engineering. It is essentially the selection of design features and options that promote cost-competitive manufacturing, assembly, and test practices.

Originators—Dewhurst & Boothroyd

Modern DFMA stems from the ideas of university professors Goefrey Dewhurst at University of Massachusetts -Amherst and Jeffery Boothroyd at University of Rhode Island [1] early in the 1980s. These Manufacturing Engineering professors came up with the concept that you could predict the assembly time, difficulty and cost by cataloging and summing all the kinematic actions it takes during assembly. This concept became so accurate that it was used to predict assembly while a product was still in the design phase. Thus, as a predictive metric, it became Design for Manufacturing-DfM. Today this technology is taught in universities and used by most large OEMs around the world. The Dewhurst & Boothroyd software (Figure 1) consists of:

The D&B techniques consist of analyzing an assembly for these features:

- The need for this part

- How many fasteners are required

- The number of different fastener types

- The number of difficult-to-assemble parts or subassemblies

- The number of motions and twist/turns involved in each assembly step

- The role of tooling and fixturing

The resulting analysis shows a:

- Total part count

- Theoretical minimum of parts or preassembled item (Pmin)

- Assembly efficiency (ease of assembly-AE)

- Assembly time

The analysis uses software to measure:

1. Prototype evaluations based on either actual or 3D models using Boothroyd and Dewhurst method.

2. Pmin is a measure of the complexity of the product. In general, the more functionality there is in a product, the higher the Pmin value.

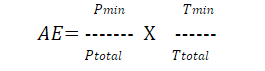

3. Assembly Efficiency (AE) is a ratio of the theoretical minimum number of parts (Pmin) to the estimated assembly time. An approximation is used to compute AE (2.933 seconds per part), so AE values are used for relative comparisons only.

Or, if Tmin/Ptotal= 2.9333 second;

AE= 2.933 sec/part X Pmin / Ttotal

Figure 1: The Dewhurst & Boothroyd DFMA software.

In 1984, NCR began a formal program on implementing design for manufacturability throughout its operation. By 1989, the program had been officially named as Design for Excellence (DfX). The company described DfX as:

“Continuous improvement in concurrent product and manufacturing process development to focus developers’ attention from the beginning on all key product lifecycle considerations such as customer requirements, quality, time to market, cost of ownership, and operational complexity.’’

There are two views on the meaning of the X in DfX:

Design for ‘X’. This suggests that the X is used as a variable term that can be substituted with, for example, Assembly, Cost, Environment, Fabrication, Manufacture, Obsolescence, Recycle, Procurement, Reliability, Serviceability, or Test.

Design for eXcellence. Suggests using all the ‘Design for’ methods to achieve excellence. This is a predictive environment where DfX is part of concurrent engineering and as part of a continuous improvement program.

In reality, both meanings should be implied. The implementation of DfX will include whichever Design for X’s the organization feels are applicable. It should also be used as part of a program or a design philosophy for achieving or striving for a level of product excellence.

Interpretations of DfX

The term DfX has different meanings to different people. The differences reflect the individual’s position in an organization and therefore exposure to it. Naturally, individual opinions are based on past experiences of the use of DfX, which can be good or bad.

Examples of perceptions of DfX are:

- An organization-wide culture

- A concurrent engineering-based methodology

- A continuous improvement tools

- A buzzword

The Benefits of Using DfX

Most a product’s cost is committed at the design stage before the product is manufactured. There are many sources that quote 75–85% of the cost of a product is committed during the design and planning activities, whereas the actual amount spent only increases during production after the design has been accepted. Figure 2 shows how design sets or influences the costs in fabrication, assembly and test. Consideration of manufacturing and assembly problems at the product design stage is therefore the most cost-effective way available for reducing assembly costs and increasing productivity.

Figure 2. Manufacturing costs are primarily driven by the design process that also can influence many other costs and support.

There is an exponential-type increase in cost of product change. This change at the production stage will typically take the form of an ECO/ECN*. The cost of change to a product is high once in manufacturing, but the cost of change is even higher when it is in use. The graph does not show the effect of cost of change once the product has been delivered. It becomes more difficult to quantify due to the intangible nature of the cost. We have control over the processes within our own organization. Unfortunately, this is not the case once the product has been delivered. Product recalls incur logistical costs, which are quantifiable, but subsequent loss of customer faith and lawsuits are not. Once the product has been delivered it becomes more difficult to quantify due to the intangible nature of the cost. We have control over the processes within our own organization. Unfortunately, this is not the case once the product has been delivered. Product recalls incur logistical costs, which are quantifiable, but subsequent loss of customer faith is not.

In conclusion, I hope I have shown you that DfM/A is not the same as Design Rule Checking (DRC), which is performed after a product is designed. DfM(X) is a series of rules, software or models that a designer uses before or during the actual design, in order to do trade-offs and optimization for a superior product, not an activity to fix mistakes.

* Engineering Change Order or Engineering Change Note/Notice.

REFERENCES

1. Boothroyd, G., and P. Dewhurst, "DESIGN FOR ASSEMBLY", Dept. of Mechanical Engineering, University of Massachusetts, Amherst, Massachusetts, 1983.