Digital On-Demand Manufacturing and a 32-Bit MCU PCB for Everyone

I proclaim that the digital “on-demand” manufacturing revolution is here! It was 1999 when I first experienced quick turn, “online” PCB fabrication. Since then, PCB fabrication services have become plentiful, inexpensive, and accessible to engineers of all levels. Online automation of full turnkey assembly is the next logical step, and I see it the future of PCB assemblies. I often say it is a great time to be alive if you are in the business of embedded systems. It has never been easier to tap into global manufacturing resources to accelerate product development.

I recently ran into a scenario where we needed to quickly adapt one of our products to a new customer application. It was a situation where we needed to be agile in our response. In this scenario, I needed to plumb a particular commercial off-the-shelf (COTS) temperature sensor into our existing cellular gateway (which only had specific digital-only ports for another application). The prototype would end up being put in a “smart” cable assembly that would adapt a new sensor into our existing system to demonstrate the concept. A small “translator” PCB with some “brains” would have to be designed to link up the sensor to our existing hardware/software platform.

Why Use On-Demand Manufacturing?

“Hustle” is an important concept when being approached with new opportunities. While many engineers think “I can build a bunch on the bench and do everything”, it is often essential to recognize that your time is valuable. Just because you can perform a task does not mean you should. We needed to quickly put together some prototypes that:

- Had the proper analog front end to interface to the customer’s sensor;

- Have enough local CPU horsepower to interface to the sensor, perform some basic processing and “talk” to via our existing protocol;

- Implement some simple power management.

None of these requirements are particularly challenging, but when you are already busy with several projects, it makes sense to call in additional resources. Having on-demand manufacturing services available can make a significant difference in your ability to be agile.

Step 1: The CPU “Glue”

I already had an analog front-end design from a previous project. What I really needed was a low-cost CPU in a small package to glue everything together. Our cellular system “talks” to our existing sensors via RS-485 interface with custom JSON messages. This application did not require a large amount of processing power. Still, it is always nice to have some overhead to ensure easy development and enable all of the diagnostic features. This is where the NXP LPC804 came in to save the day.

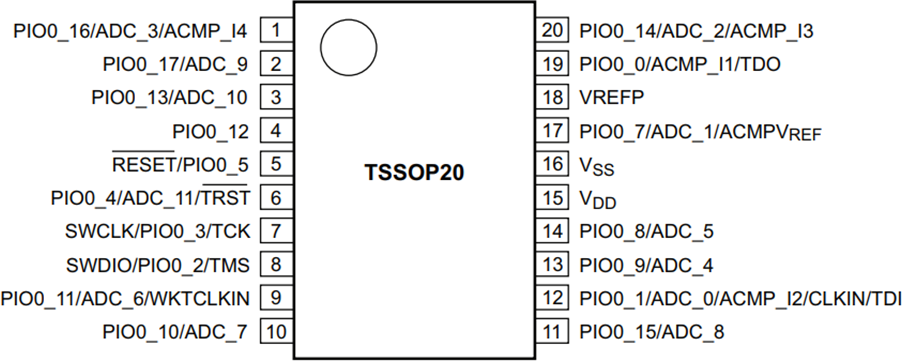

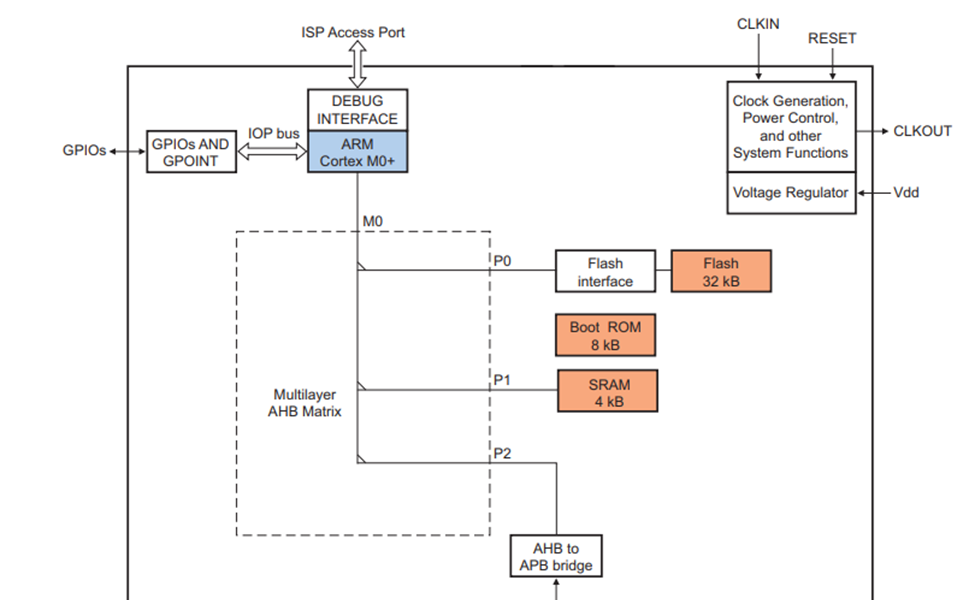

The LPC804 is based on a 32-bit ARM Cortex M0+ CPU with peripherals attached to implement useful glue logic. This component is available in an easy-to-use TSSOP20 package. In production quantities, a price tag of $0.42 makes it a very attractive part. This type of application generally screams “8-bit” but the easy to use package, price and features make it a no-brainer to go with a 32-bit microcontroller. A couple of other things I love about this part:

- It has a bootloader baked in ROM. This means you can program this part over a UART to ease production programming.

- It has flexible pin mapping. Instead of a pin-mux, the peripherals can be mapped to any GPIO IO pin.

- A small amount of programmable logic.

This chip is truly awesome for these types of glue logic applications. With 32 KB of Flash memory and 4 KB of SRAM, you can get quite a bit accomplished. If you have not moved into the 32-bit space, the LPC804 is a great way to learn 32-bit ARM Cortex-M0+ architecture. It is approachable for a beginner from both the hardware and software aspects. Many modern 32-bit based MCUs come with reference manuals that have thousands of pages. A part like the LPC804 is a great way to get initiated into the 32-bit ARM cortex ecosystem without being overwhelmed.

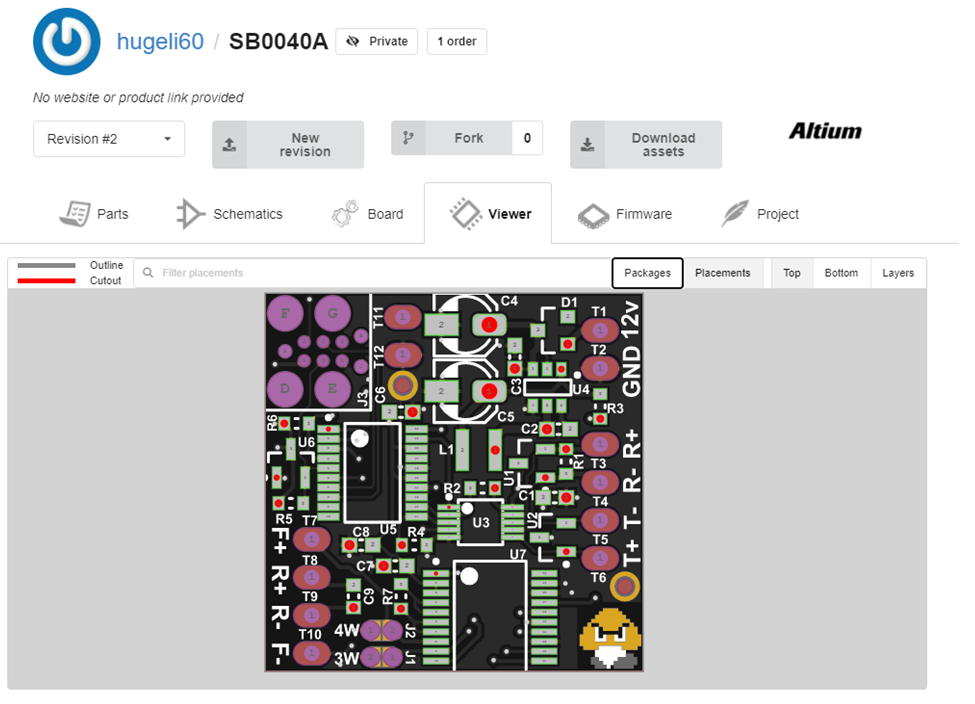

By starting with this MCU, I was able to quickly put together a prototype that would move the ball downfield towards delivery. After a quick huddle with the team, we came up with a simple board that could be assembled “inline” with our standard cable interface.

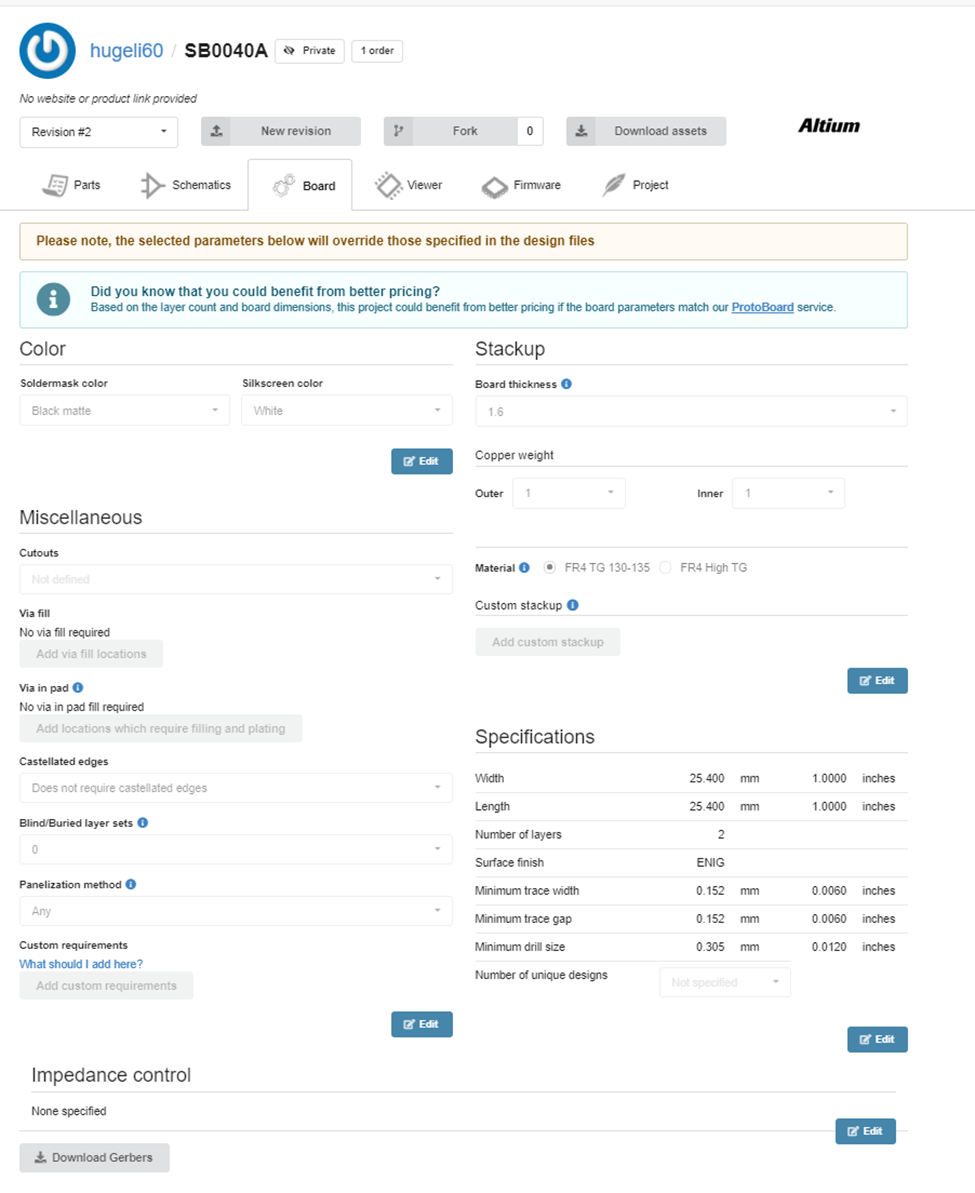

Step 2: Getting Prototypes

While this particular design did not have a large number of components, I could quickly wrap up a couple of days in ordering parts, building and testing the boards. This time could be better spent working on firmware, coordinating with the customer on specific interface features and everything else that will make us money. I turned to CircuitHub for fabrication. In a previous article, I used the turnkey service PCB.NG to build the “Mini-Monkey”. Like PCB.NG, CircuitHub has an excellent online interface to upload files and manage the design.

Having visibility into the manufacturing and process is a key benefit for me. With traditional CMs, you often dump a documentation package and wait days (or even weeks) to know the price, delivery, etc. I even compared volume pricing through CircuitHub with some designs I already have been produced at traditional CM’s. At our volumes, the price was on par with my existing providers. The key take-away is that an on-demand manufacturing services gives you the price right away, you don't have to go through the trouble of working up your own manufacturing estimate. There is a convenient “slider” to help you understand volume pricing instantly.

For this order, I paid $561.30 to get my prototypes to get built. Could I get raw PCBs, parts, and do the assembly for that price? Nope! Not If one is honest about the value of their time. Engineers often significantly undervalue how much they cost per hour. Being honest about the number often reveals that they are not the cheapest way to get things done.

Step 3: Receive and Test

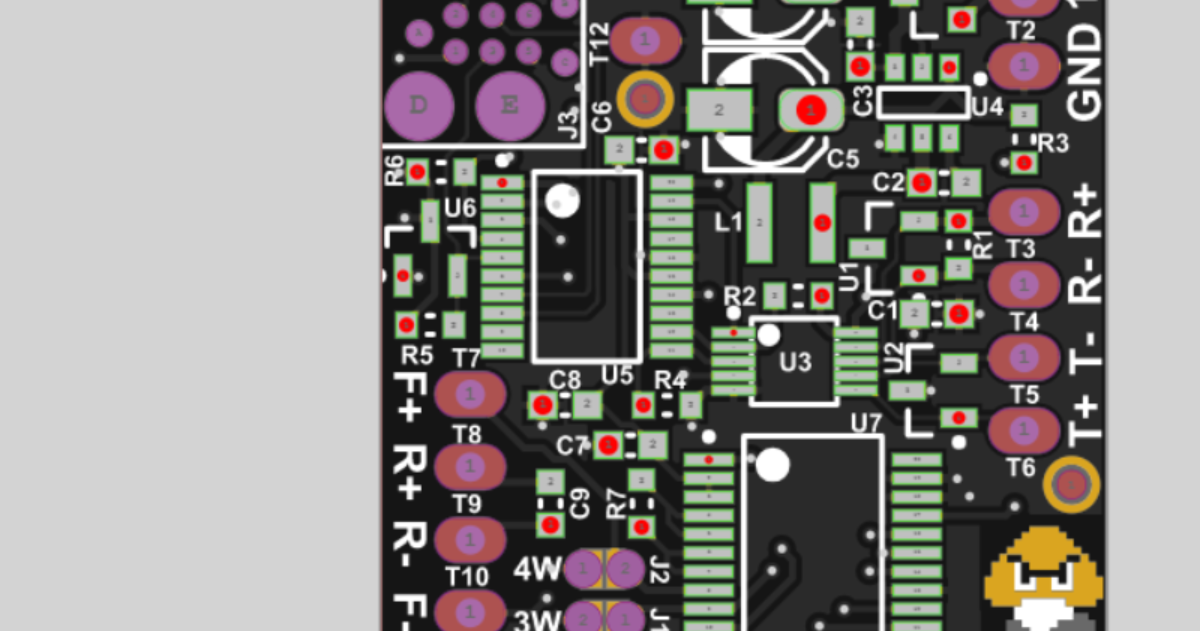

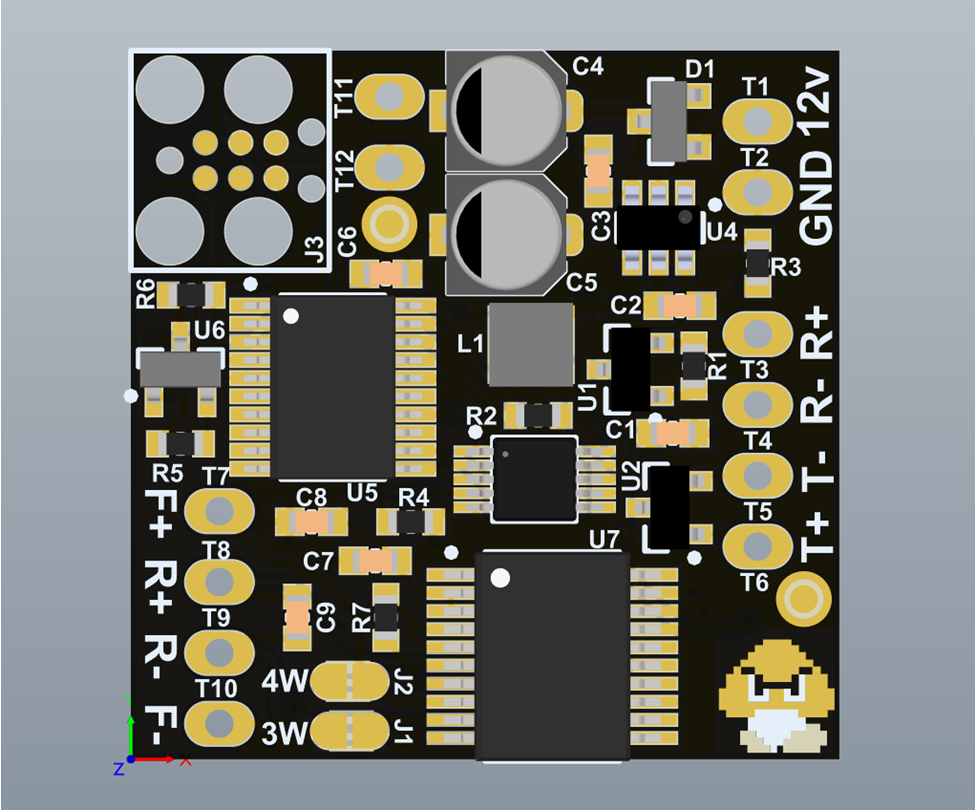

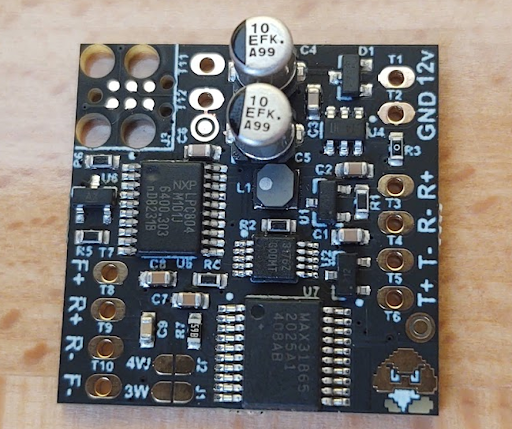

So, how did these on-demand prototypes turn out? Take a look and see for yourself!

.png)

As always, there is plenty of room for neat artwork!

The result was fabulous, and the prototypes were delivered on time. Another nice feature was that all communication occurs through the web interface. There was one part I needed to substitute, and having a centralized location for communication was beneficial when there are several people involved in a project. As icing on the cake, they provide a photo of the completed assembly before they ship. I found that to be a particularly nice “warm and fuzzy” benefit of the process.

I am quite excited to see more of this type of on-demand manufacturing and the new products it will enable. Couple the new on-demand manufacturing technologies with the accessibility of 32-bit processing power, it has never been easier to develop and produce new boards! I would highly recommend CircuitHub and microcontroller technologies such as the NXP LPC804. These services really do make my engineering life easier.

Cheers!

Would you like to find out more about how Altium Designer® can help you with your next PCB design? Talk to an expert at Altium.